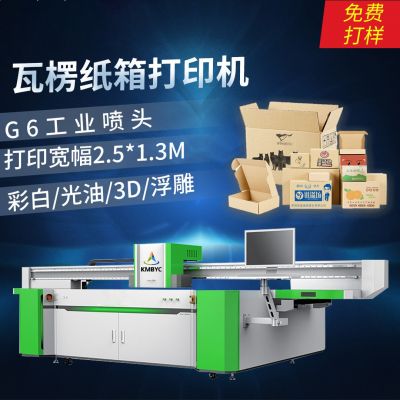

尺寸:530×380×340mm

重量:30kg

粉笔规格:大头X小头X长:10 mmX8mmX75mm

产量:0.2~0.4万只/小时,

模具规格:400只/模 一个人操作

Specifications:

1.free of dust

2.great treatment ability

3.wearable- resistant and longevity/durable

400-1 chalk machine has one mold, manual mixing.

A person can operate three machines, packaging needs of a person.

Model: 400-1

Production: 2000-4000 pieces/hour

Mold size: 400 pieces/per mold

Chalk size: 10 mm*8 mm* 75 mm

The machine size: 530mm x 380 mmx 340mm

Weight: 35 KG

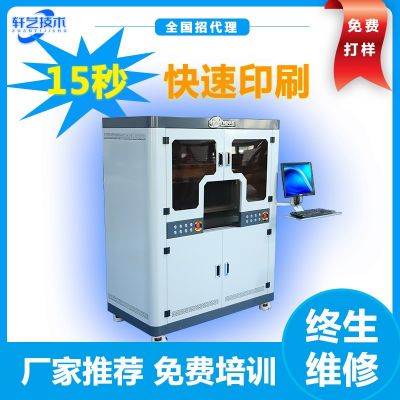

Chalk production process

1. Mold evenly brush oil, brush back and forth with a wide brush, brush the new mold should be more oil.

2. The mold plate moving up and down a few times, the screw top and the bottom plate comes into contact.

3. Turn on the water, turn on the water with a movable foot switch pedal to pedal in the end, until the water in the water last. (First mold first feed, add water)

4. Addition, the quantitative good gypsum powder into the mixing bucket.

5. Mixing, stirring for 10-20 seconds to start the motor.

6. Put the pulp, put a good brush oil stirred to die bottom of the barrel, hit the switch to open the pulp slurry was stirred well into the mold until the stream last.

7. Calibrating with a plastic scraper to scrape the pulp mold hole, scrape out the remaining pulp mold mouth gelling.

8. A mold, a new mold die not too late. Chalk can feel a little hard to top 2-5 mm, 1 to 2 minutes over again ejection.

通过

通过